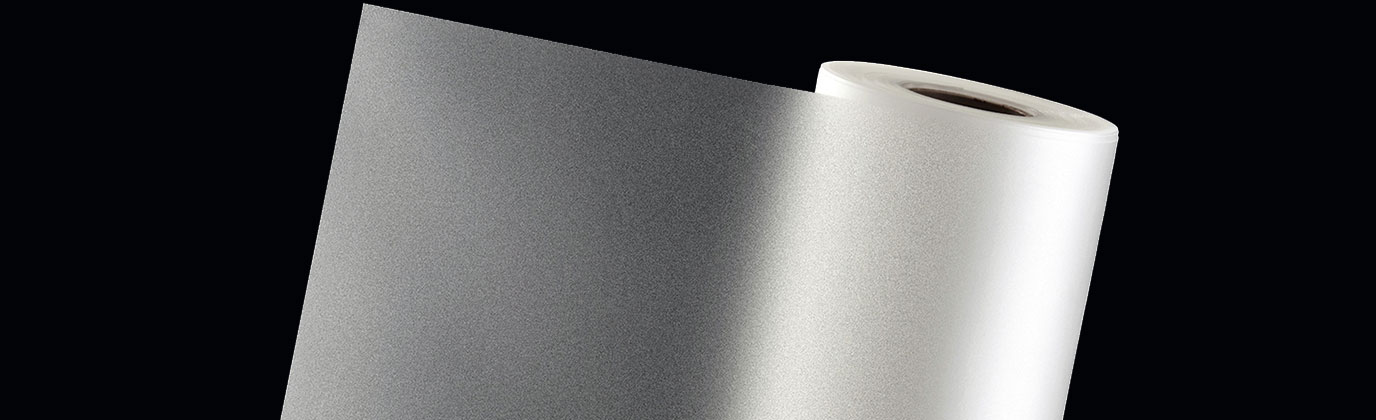

Lamination to Glass

Photovoltaic Solar Energy is an important chemical product in the production of panels.

It is a nylon-looking material used in Solar Panels to provide adhesion of Glass, Cell and Cell Backsheet under the temperature.

After all the operations are carried out on the panel production line, it enters the lamination machine. Here, at a temperature of 180 degrees, under vacuum, all layers adhere to each other via EVA.

EVA melts and performs an excellent adhesive task.

After this process, it is no longer possible to separate any layers, glass or cells of the solar panel.

Excellent durability (High temperature, high humidity and weather resistant, long life)

Full homogeneous adhesion between glass-cell-backsheet

Excellent encapsulant in lamination process

Excellent optical transmission and transparency

Excellent flexibility against physical stress during lamination process

Dielectric character

EVA film provides homogeneous PV (photovoltaic) encapsulant with excellent lamination between solar cell and glass and solar cell and backsheet. This provides long-term protection for the most sensitive parts of PV modules with high performance and durability. This feature increases module durability and production efficiency.

EVA solar film, with excellent grip and adhesion (encapsulant), penetration of water and micro dust into PV modules, plays an important role in preventing dirt, protects solar cells by softening impacts and vibrations. It provides maximum satisfaction due to its high efficiency, minimum maintenance costs and long life.